Sensitive throttle EJ25 soloution

I had battled with a very sensitive throttle in the BH Outback for 2 years.

What the issue is, is you only need the top 10 to 15mm of the pedal for normal driving. This is plenty to accelerate you to 100kph in a respectable time. You may think this is great, the car has so much power! But in reality this makes it extraordinarily hard to keep a constant speed.

My first thought was the throttle body was too large for the engine, it is 65mm or so for a 2.5! The accelerator pulley is also quite small, meaning it doesn’t take much cable movement to open the butterfly up full. I saw on some other cars at the wreckers a snail shaped exponential pulley. The Subaru ones are linear meaning the movement on the pedal is directly proportional throughout the entire range to the movement on the butterfly. The exponential pulley allows the the beginning of the pedal to slowly open the butterfly while the further down the pedal you press the faster it opens the butterfly. This is what I felt the EJ25 needed to desensitise the start of the pedal, but ensure it can still go WOT (wide open throttle).

These are the only photos I took of the throttle pulley. I went looking through wrecked cars to a pulley similar in size but with an exponential snail on them. This one I believe came from a Hyundai Excel (90’s model) but my memory is hasy.

I had to cut/weld/grind it to fit.

This helped a bit, but it still leached away when even applying the smallest amount of throttle. I felt this could not be the TB (throttle body) butterfly because there was no way just a mm of movement could give the car that much air to accelerate. So I plugged in the computer using a OBD to USB cable and FreeSSM and RomRaider software. After mapping some driving using RomRaider I found the IAC (idle air control) valve was acting weird.

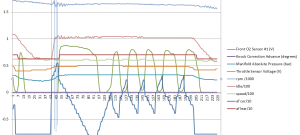

This is a log of going off the throttle at 50kph to on the throttle (where the vertical blue lines are) just a little.

As you can see by that once the TPS (throttle position sensor) measures a reading above “idle” the IAC valve opens half way. This makes no sense as I would expect the IAC to close until needed for idling. Never the less though, it opens when the accelerator is pressed. This causes a jump in the amount of air the engine is getting which in turn causes the engine to rev up with only a tiny bit of throttle pressure, less than 3mm of pedal movement.

With this extra air the engine is getting through the IAC it is impossible to keep the car driving on a flat at a constant 40kph in any gear. Very annoying.

As the ECU is a 16bit model it isn’t programmable. And because the loom is different to the later 32bit models it isn’t possible to upgrade ECU easily. So I took a different approach. I figured, all the IAC needs to do is hold an idle with the aircon on in all conditions. So if I were to limit the IAC’s ability to give more than just enough required air I could perhaps lessen this learching/jolting/jerking effect.

What I came up with is physically limiting the air that can pass through the IAC.

This 16mm tapered plastic tube with a 4mm hole only allows enough air through to the IAC to allow idle with AC on.

When you press the accelerator, the IAC opens wide, but is limited to only breathing through that 4mm hole.

It does whistle, but it can only be heard when the airbox is removed.

This made the most difference, and now the sensitive throttle is handlable. I still wish the TB was smaller on this engine to allow for better throttle control. I’ve seen 4.2l Diesels with smaller TB!

This plastic tapered plug I printed using ABS on a 3D printer. If you’re interested in doing this mod and want one shoot me an email!